Footwear manufacturing machinery

Release time:

2024-05-29

Footwear manufacturing is a complex process that requires specialized machinery to efficiently produce high-quality shoes. From cutting and stitching to finishing and packaging, each step in the manufacturing process relies on different types of machinery to ensure that the final product meets the standards of the footwear industry.

Footwear manufacturing is a complex process that requires specialized machinery to efficiently produce high-quality shoes. From cutting and stitching to finishing and packaging, each step in the manufacturing process relies on different types of machinery to ensure that the final product meets the standards of the footwear industry.

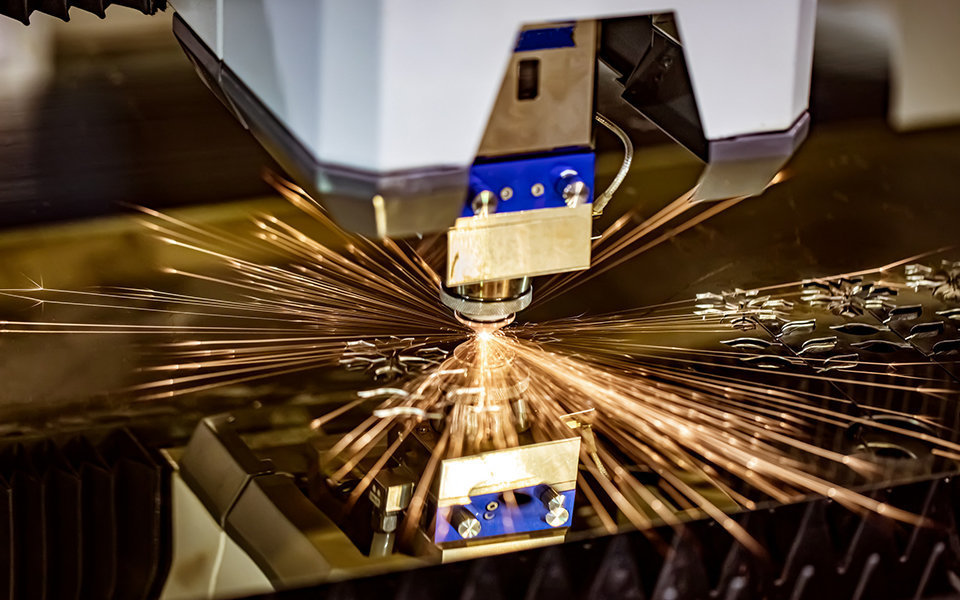

Cutting machinery is the first step in the footwear manufacturing process. This machinery is used to cut out the various pieces of material that will be used to construct the shoe. There are different types of cutting machines available, including die cutting machines, clicker presses, and laser cutting machines. Die cutting machines use sharp blades to cut through multiple layers of material at once, while clicker presses use a hydraulic press to cut out individual pieces. Laser cutting machines use a high-powered laser to cut out precise shapes with minimal waste.

After the material has been cut, stitching machinery is used to assemble the pieces of the shoe. Stitching machines come in a variety of types, including flat bed machines, post bed machines, and cylinder bed machines. Flat bed machines are used for stitching flat pieces of material, while post bed machines are used for stitching in hard-to-reach areas. Cylinder bed machines are used for stitching in cylindrical or curved areas of the shoe. These machines use various types of stitches, including lockstitch, chain stitch, and overlock stitch, to secure the pieces of the shoe together.

Once the shoe has been stitched together, finishing machinery is used to clean up any rough edges and add decorative elements to the shoe. Finishing machinery includes trimming machines, skiving machines, and embossing machines. Trimming machines are used to cut off any excess material and create clean edges on the shoe. Skiving machines are used to thin out the edges of the material to reduce bulk and create a smooth finish. Embossing machines are used to add decorative patterns or logos to the surface of the shoe.

Finally, packaging machinery is used to prepare the finished shoes for distribution. Packaging machinery includes shoe box making machines, labeling machines, and shrink wrapping machines. Shoe box making machines are used to create the boxes that the shoes will be packaged in. Labeling machines are used to attach labels with size and branding information to the shoes. Shrink wrapping machines are used to wrap the shoes in plastic film to protect them during shipping and storage.

In conclusion, footwear manufacturing machinery plays a critical role in the production of shoes. From cutting and stitching to finishing and packaging, each step in the manufacturing process relies on specialized machinery to ensure that the final product meets the standards of the footwear industry. By investing in high-quality machinery and staying up-to-date with the latest technological advancements, footwear manufacturers can increase efficiency, improve product quality, and stay competitive in the global market.

Keywords: