Footwear manufacturing and repair machinery

Release time:

2024-05-29

Footwear industry plays a crucial role in the global economy, providing a wide range of shoes to meet the diverse needs of consumers. In order to produce high-quality footwear efficiently, manufacturers rely on advanced machinery for both manufacturing and repair processes.

Footwear industry plays a crucial role in the global economy, providing a wide range of shoes to meet the diverse needs of consumers. In order to produce high-quality footwear efficiently, manufacturers rely on advanced machinery for both manufacturing and repair processes.

Manufacturing machinery used in footwear production includes cutting machines, sewing machines, lasting machines, sole attaching machines, and finishing machines. These machines are essential for cutting, sewing, lasting, attaching soles, and finishing the shoes. Cutting machines are used to cut the patterns of the shoe upper from the material, while sewing machines stitch the upper parts together to form the shoe. Lasting machines shape the shoe upper around the shoe last, and sole attaching machines attach the sole to the shoe. Finishing machines are used for trimming excess materials, polishing, and adding final touches to the shoes before they are packaged and shipped to retailers.

Repair machinery is also important in the footwear industry as it allows consumers to extend the life of their shoes by fixing minor damages or wear and tear. Common repair machinery includes shoe repair machines, sole presses, heel presses, and stitching machines. Shoe repair machines are versatile and can be used for various repair tasks such as replacing soles, heels, and stitching. Sole presses and heel presses are used to attach new soles and heels securely to the shoes. Stitching machines are essential for repairing seams and stitching on the shoes.

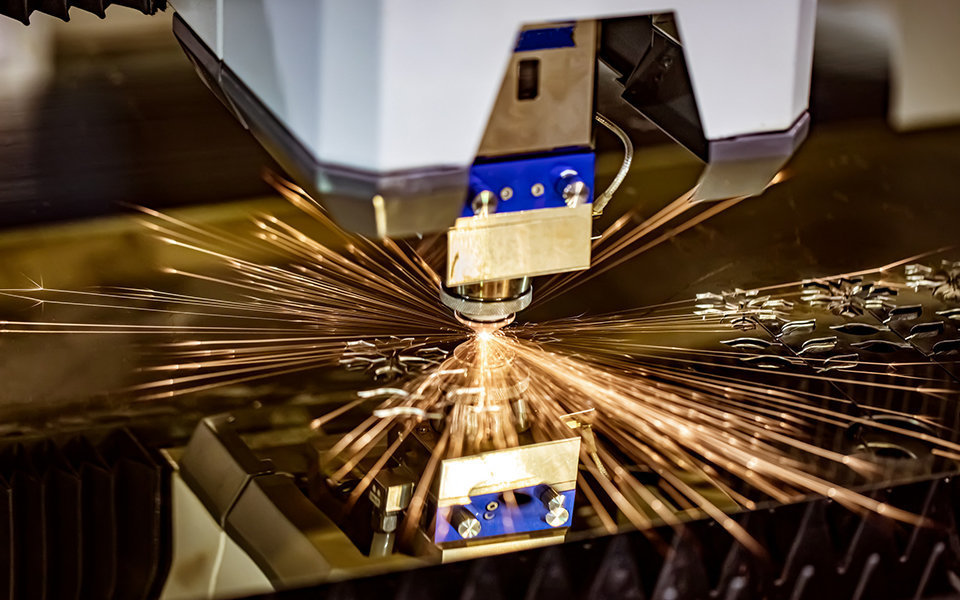

In recent years, there have been significant advancements in footwear manufacturing and repair machinery to improve efficiency, productivity, and quality. Automated machinery with computerized controls and sensors have replaced manual labor in many processes, leading to higher precision and consistency in shoe production. CNC (Computer Numerical Control) machines are now widely used in cutting, shaping, and engraving shoe components with high accuracy. 3D printing technology is also being adopted in shoe manufacturing to create customized and unique designs quickly.

Furthermore, eco-friendly machinery is gaining popularity in the footwear industry as manufacturers aim to reduce their carbon footprint and minimize waste. Sustainable materials and energy-efficient machinery are being used to produce shoes in an environmentally friendly manner. Recycling machines are also being utilized to repurpose old shoes and materials into new products, contributing to a circular economy.

In conclusion, footwear manufacturing and repair machinery play a vital role in the footwear industry, enabling manufacturers to produce high-quality shoes efficiently and consumers to maintain and repair their shoes effectively. With continuous advancements in technology and a focus on sustainability, the future of footwear machinery looks promising, promising further innovation and improvement in the industry.

Keywords: